Takamine Whiskey

Revival of a 19th Century American experiment.

Takamine Koji Whiskey is made with the patented Takamine Process, which uses an ancient Japanese mold, koji, to convert starches to sugars in a process similar to malting barley. Unlike malt whiskey where sugars are extracted in a warm water mash before yeast is introduced to start the fermentation, both the koji and yeast are active at the same time in a multiple parallel fermentation. This 100% barley ferment is then double distilled and aged in virgin oak and ex-Bourbon casks to give the spirit its natural golden color and deep, lush flavors.

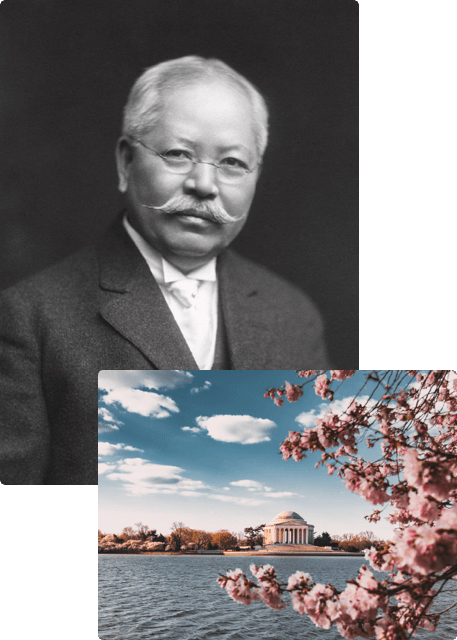

Top: Takamine Whiskey is made with 100% 2-row barley. Bottom: Shinozaki Distillery’s barrel aging warehouse in Ukiha City is a former municipal grain bunker.

Koji mold growing on barley.

For over 1,200 years Japanese craftspeople have used koji as the foundation of Japanese fermentation. Soy sauce, miso paste, mirin cooking wine, sake, and other classic Japanese foods and beverages would not exist as they do today without koji. Koji is so central to Japanese culinary traditions that it has been designated the national mold of Japan (that is not a joke). When carefully cultivated on rice, barley, or other grains koji creates an amylase enzyme, which converts starches to sugars. This allows yeast to do its job. In fact, koji is so efficient that Japanese sake is the highest natural alcohol fermentation in the world with some sake reaching above 20 percent alcohol. In the case of Takamine Whiskey, koji mold is propagated on steamed pearled 2-row barley and nurtured for two days in an environment with perfect heat and humidity to optimize koji growth. This kojified barley is then moved to a fermentation tank where water, yeast, and additional freshly steamed barley are added. This fermentation process lasts nearly 2 weeks during which the koji will continue to convert the barley to sugars for the yeast to make alcohol. The final fermentation is 19% alcohol.

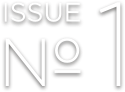

Jokichi Takamine (1854-1922) was born into a sake making family before graduating from Tokyo Imperial University. The young biochemist spent his early career finding medicinal uses for koji which included patenting Takamine Diastase, a stomach aide, that would go on to be popular in both the US and Japan. He was encouraged to move to Chicago in 1890 due to the Illinois Whisky Trust’s interest in his Takamine Process, which he patented in 1891. Experiments began at the Manhattan Distillery in Peoria, Illinois, but the building was destroyed in a mysterious fire shortly thereafter.

Takamine’s whiskey would not reach production until December 1894, but this would be short lived. The distillery entered receivership in early 1895 and the new owners returned to standard malting, abandoning the new process. Professor Takamine would move to New York City where he would have a very successful career as a chemist, even isolating adrenaline for the first time. In 1910 he donated over 2,000 cherry blossom trees to Washington DC, which still bring joy to visitors today.

His whiskey dream was never realized.

“Portrait of Jokichi Takamine (1854-1922),” circa 1910. Williams Haynes Portrait Collection. Box 14. Science History Institute, Philadelphia (left). Professor Takamine’s cherry trees around the DC Tidal Basin (below).

Shinozaki Brewery & Distillery staff, circa 1920 (left). The Asakura Region of Fukuoka is known for its agriculture and its famed triple water wheels (above).

Shinozaki Brewery and Distillery has been making premium sake since the mid-1800s and has been creating beautiful koji spirits since 1979. Nearly four decades ago, Michiaki Shinozaki, learning of Professor Takamine’s story, was inspired to revive the Takamine Process in Japan. He experimented with fermentation types, distillation methods, and barrel aging until he and his team of craftsmen had found the perfect expression. His family acquired a former municipal grain storage warehouse to expand barrel aging capacity in order to ramp up production.

Finally satisfied with the whiskey he created, Mr. Shinozaki approached the Takamine Family Trust for permission to use the professor’s name. They agreed, the first time the trust has ever granted the use of his name for a commercial product.

At long last, the Takamine Process can be experienced by the great grandchildren of Takamine’s intended customers.